Research and Teaching Facilities

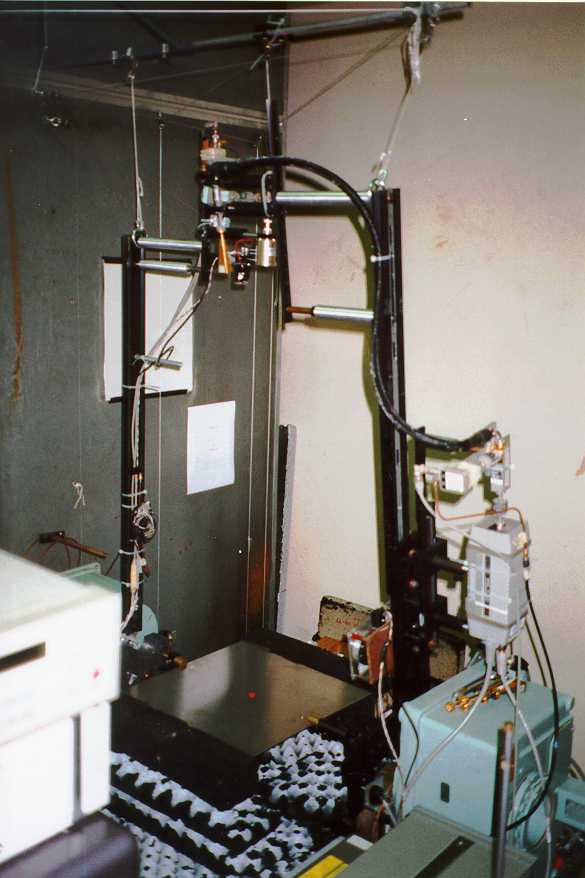

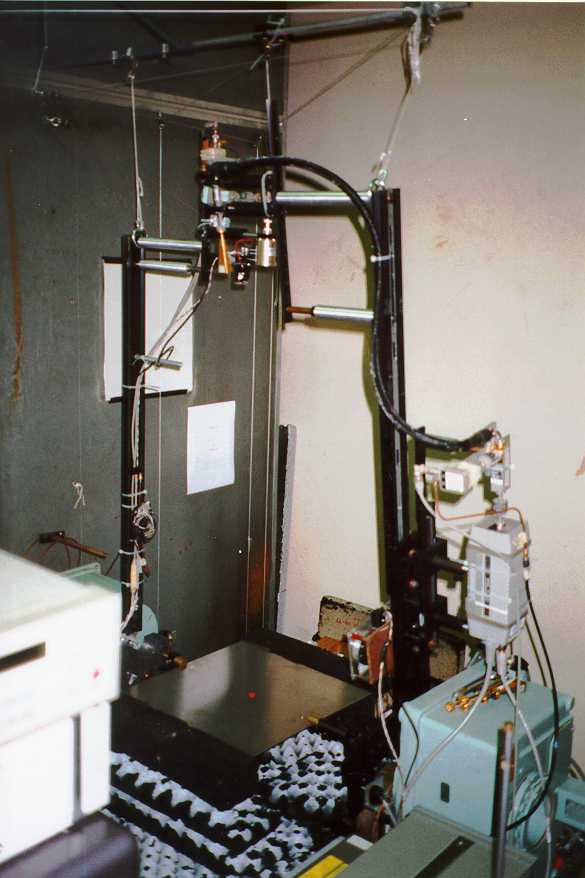

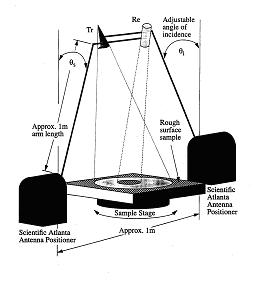

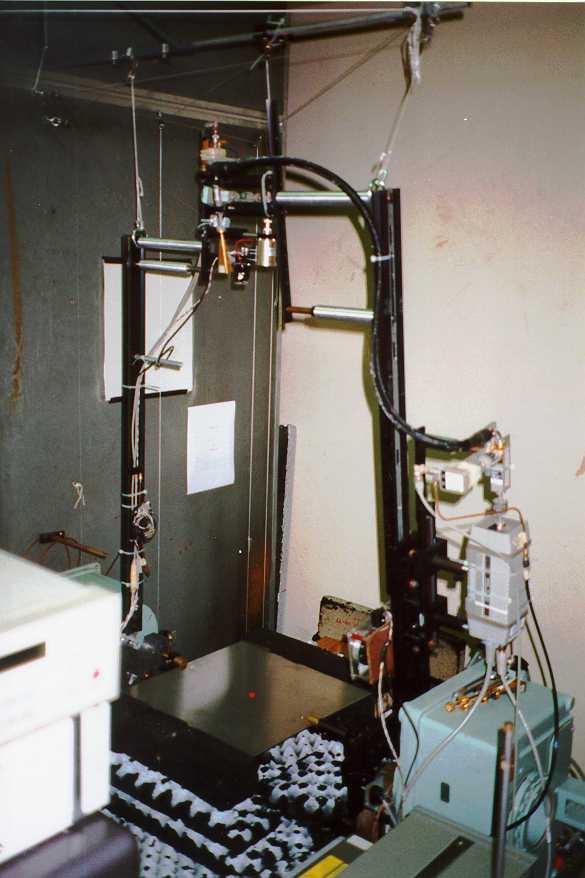

The millimeter-wave (MMW) bistatic scatterometer at

the University of Washington is based on the

HP8510C MMW vector network analyzer (VNWA).

Extensive modifications were made to the front-end part of the system to convert

it to a fully polarimetric scatterometer setup. The HP83621 synthesized

frequency sweeper generates a microwave signal from 12.5 to 18.3 GHz. The

amplified and frequency-leveled microwave signal is then multiplied by 6 to the

MMW frequency, 75-110 GHz. In a fully polarimetric operation, the transmitted

signal polarization is controlled by a rotational angle of a lambda/2 wave plate

in front of the transmitting antenna. The two orthogonal polarizations received

by the dual-polarized receiving antenna are down converted by harmonic mixers.

Positioning Systems

Both

Tx and Re antennas are mounted on the

stepping-motor-controlled Scientific Atlanta stages. The Re antenna can be moved

from -100 to +100 degrees with an angular resolution of less than 0.1 degrees.

This allows the users to conduct both transmission and near-grazing experiments with the same system. The Tx

antenna stage can be moved so that the receiver can be placed at any point on a

hemispherical shell surrounding the sample. The sample is mounted on the

rotational or translational stage and placed at the center of rotation of the Re

antenna. The maximum size is 1 meter in diameter and 20 cm in thickness.

CAD/CAM Rough

Surface Fabrication System CAD/CAM Rough

Surface Fabrication System

We have a unique capability of

fabricating rough

surfaces of different surface parameters. Our system consists of surface

generation software and a CAD/CAM system. The milling machine has a resolution

of less than 10 mm. The maximum surface size that can be fabricated with this

system is approximately 20’x30’.

Optical

System Optical

System

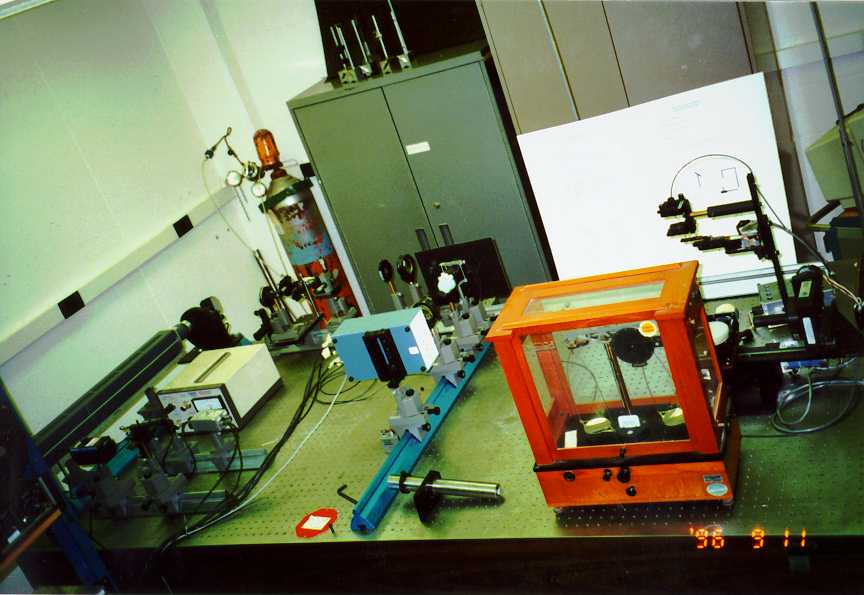

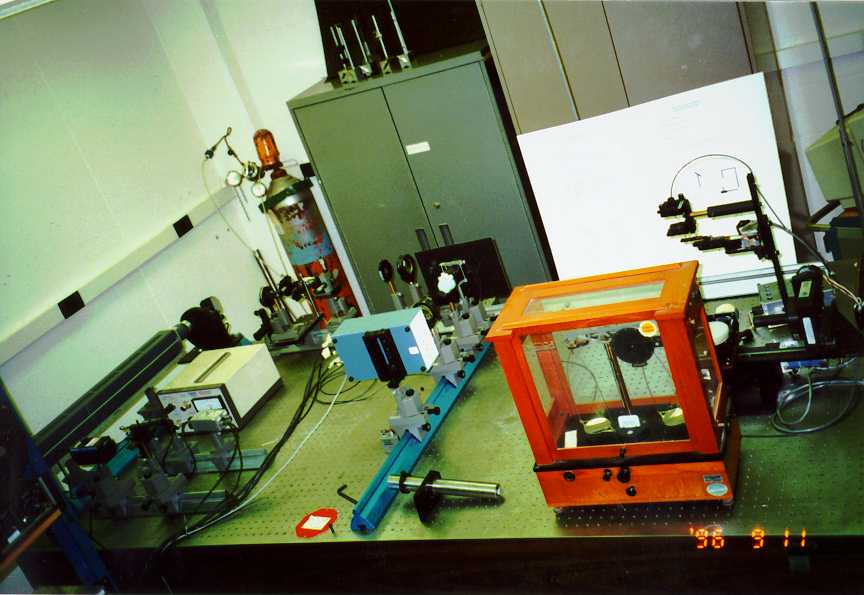

A

complete bistatic and fully polarimetric optical scattering system is also

available for this project. This system is mounted on a 4’x8’ optical bench and

the data acquisition is completely controlled by computer. A 4x4 complete

Mueller matrix is obtained by transmitting 4 different polarizations and

measuring the scattered intensity using 6 different polarizers.

Microwave ,

MMW Material Characterization Microwave ,

MMW Material Characterization

We have

extensive microwave equipment including Agilent/HP vector network analyzers

(8510C, 8720E, 8722ET), an antenna range, and anechoic chamber. Our antenna

range has been used for both teaching microwave classes and research involving

the design of antennas. We have also developed a 75-110 GHz fully polarimetric

bistatic scatterometer, 30-40 GHz radar, and circular microwave imaging systems.

We have also developed hardware and software for microwave/millimeter-wave

material characterization systems. These systems can be used for our experiments

to verify our theoretical results. We have computer facilities for our

numerical work on Monte-Carlo simulations, integral equation solutions, imaging,

and metamaterial research.

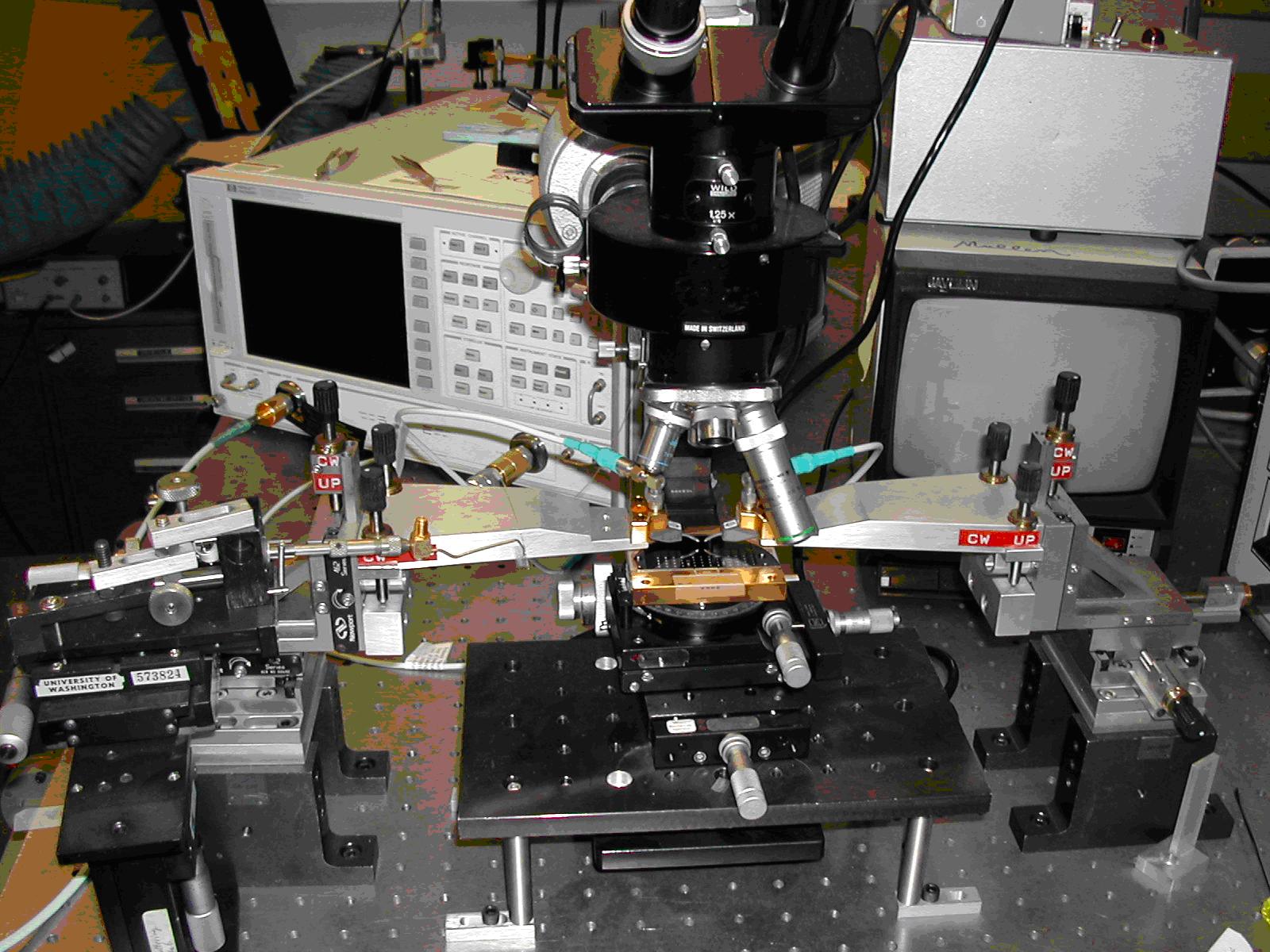

Microwave probe station for material and device characterizations.

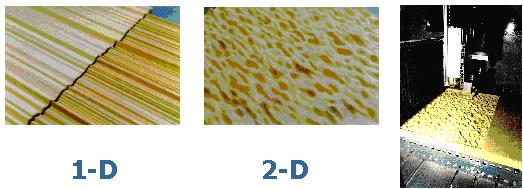

Random rough surface

created by computer-controlled surface milling machine.

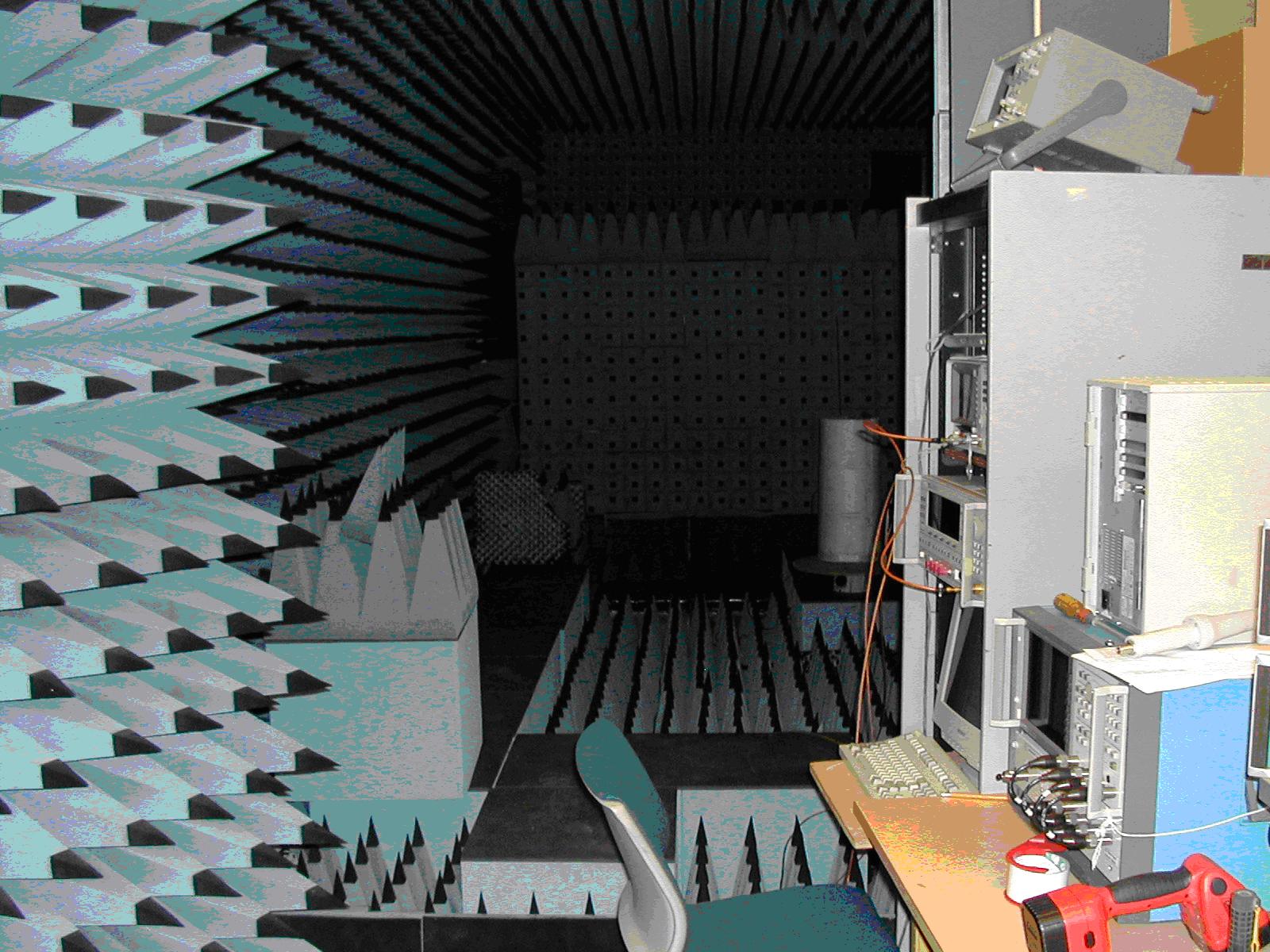

Left: Anechoic chamber

and antenna measurement system. Right: W-band (75-110 GHz) and V-band

(50-75 GHz) systems for transmission and reflection measurements.

Millimeter-wave

bistatic measurement system

|